Michigan takes first place at Exoskeleton Competition

The STARX suit helps first-responders bear greater weights and spend less energy.

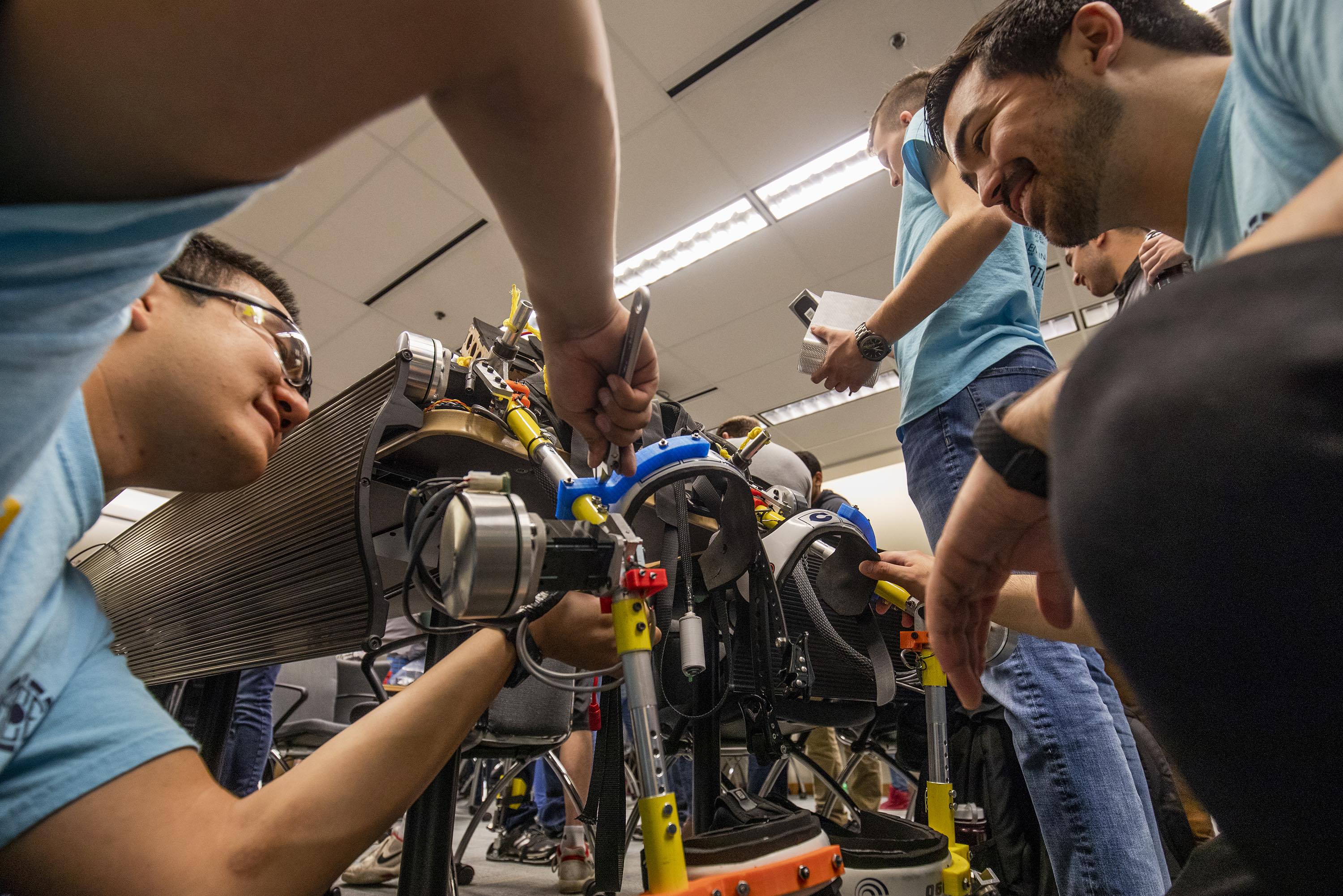

Photos by: Robert Coelius/Michigan Engineering, Communications & Marketing

Enlarge

Enlarge

Michigan took first place at this year’s Applied Collegiate Exoskeleton (ACE) competition held in Ann Arbor. While there are many uses for exoskeletons, or robotic suits, the ACE competition evaluates suits that are designed to serve first responders. The suits should augment the strength of the wearer while also reducing the metabolic load, or the amount of energy the wearer expends.

“There’s such a high physical load on first responders, so reducing the amount of energy they expend enables them to think more clearly, and then hopefully they can get more people out,” says Owen Winship who graduated this spring with a BSE in CE and will be returning in the fall as an ECE master’s student. Winship served as the Electrical and Controls lead of the Michigan team, STARX.

STARX – named after “I am Iron Man” Tony Stark – stands for Strength Augmenting Robotic Exoskeletons. The team was formed in 2015, and they founded the ACE competition, now in its second year, with the goal of popularizing exoskeletons.

Exoskeleton research and design is relatively new compared to other robotic technology, and STARX wanted to encourage greater awareness of exoskeletons and their possibilities to the general public. They created the ACE competition to incentivize students from other schools to form their own exoskeleton teams to make the work more visible to the public and to advance the research.

Enlarge

Enlarge

“We have almost no body of experience to draw on,” Winship says. “We get to work on a very unique design challenge, which I find really fascinating.”

This year, the competition took place May 17th and 18th and featured teams from the Colorado School of Mines, the University of Nebraska-Omaha, Michigan State University, and Dordt University. Judges were comprised of U-M professors, corporate sponsors, and current and former first responders. The first part of the competition is a design review where the judges and fellow teams examine the overall design of the exoskeleton. The second part of the test is a mobility test, where a team member puts on the suit and has to navigate an obstacle course.

“There are a lot of goofy ‘exoskeletons’ videos where someone straps a car jack to their legs, and they call it an exoskeleton, and they can lift a car – cool – but they can’t move while they do it, so it’s useless. It’s completely useless,” Winship says. “The obstacle course is meant to test the practicality of the exoskeleton and verify that this would actually be useful in a real-life situation.”

The final part of the test is a metabolic test. The competitors are given a 30lb weight (reduced from the original 75lb requirement) and they then must navigate the obstacle course four times: once without the exoskeleton or weight, once with just the weight, once with just the exoskeleton, and finally once with the exoskeleton and weight.

“We compare the metabolic data to figure out if the exoskeleton is actually helping you or, at the very least, it’s not harming you,” Winship says.

STARX won the maximum amount of points from each obstacle test and took first place.

MENU

MENU